| Name: | NAGAE VIETNAM Ltd. |

|---|---|

| Established: | 26th March, 2013 |

| Address: | Lot J-10, Long Duc Industrial Park, Binh An Ward, Dong Nai Province, Viet Nam |

| Capital: | JPY 350,000,000 (VND 70 billions) |

| Representative: | Toshiaki Kaizu (President) |

| Employees: | 90 (inc. 3 Japanese) |

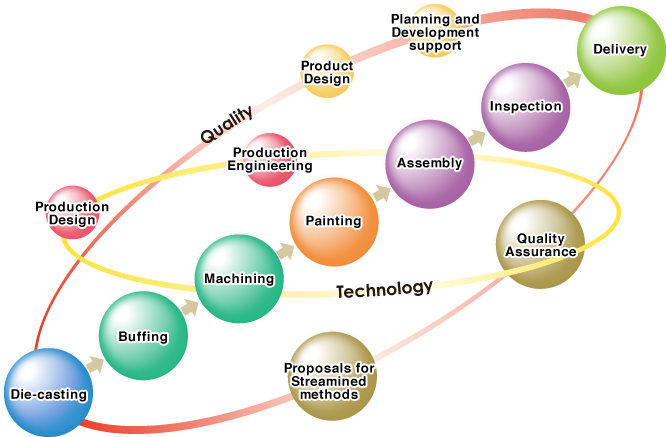

| Business Description: | Die-casting (aluminium), processing,painting, assembly |

| Main products: | industrial products, building materials, medical equipment |

| Land space: | 10,000m2 |

| Building space: | 5,000m2 |

| Head Office: | NAGAE Ltd. (in Japan) |

| From HCM city: | - 40 km to the east |

| From port: | - 30km away from the Cat Lai Port |

1. Knowledge of your business

development team with extensive metalwork expertise

– proprietary technology that proves understanding of your operations

2. Adequate investment

– staff: certified and reliable staff

– machines: cutting-edge machines imported from Japan

3. Ability to fully support you need

– quick response

– accurately assess to the situation

Our flexible manufacturing system creates the optimal lines for your products.

We operate Japan's latest high-speed die casting machines (from 125 tonnes to 350 tonnes) to manufacture high precision products made of aluminium.

- Material type that we can do casting: Aluminium (ADC12)

The process is operated by high accuracy machining centres. Our high-skilled engineers who were trained in Japan ensure the accuracy of machining quality.

Buffing is the process for smoothing the surface of your products.The process uses wheels and compounds to polish. Our experienced team analyses and chooses a suitable application for your products.

Automatic polishing machines are also used.

Total automatic painting system from diping in primer to baking finish.

You can be assured that the quality is as good as that in Japan.

– Coating type that we can do: liquid coating system

To meet a wide variety of customers’ demands, we apply 'cellular manufacturing system' to assemble finished products. The system reduces lead times, resulting in the ability for us to manufacture high quality products at a low cost, on time, and in a flexible way.

Equipment |

Spec |

Q'TY |

|---|---|---|

| Die-casting Machines | 125t machine (Toyo Machinery & Metal) |

1 |

| 250t machine (Toyo Machinery & Metal) |

1 | |

| 350t machine (Toyo Machinery & Metal) |

2 | |

| Die-casting Machine Periphery | Shot blasting machine | 2 |

| Machining Tools | Machining centre (FANUC) | 5 |

| Buffing machine | 6 | |

| Automatic polishing machine | 1 | |

| Measuring Instruments | 3D measuring machine | 1 |

| Emission spectrometer | 1 | |

| Painting Line | Painting with baking system | 1 |

Copyright(c) NAGAE Ltd. All Rights Reserved.